The craft of coffee roasting is being reshaped by global market forces and the rapid adoption of technology. While tradition and artistry remain central, roasters are under pressure to meet growing demand for consistency, sustainability, and traceability. Macro trends are steering the industry in new directions, while technological innovations are redefining what’s possible inside the roasting plant.

Macro Trends in Coffee Roasting

1. Rising Demand for Consistency

As specialty coffee continues to grow, consistency has become a non-negotiable expectation across the value chain. Wholesale buyers—from cafés to large retail chains—want assurance that every bag they purchase will deliver the same flavor profile week after week. Consumers, too, are increasingly attuned to subtle differences in taste, and loyalty can be won or lost based on a single inconsistent batch.

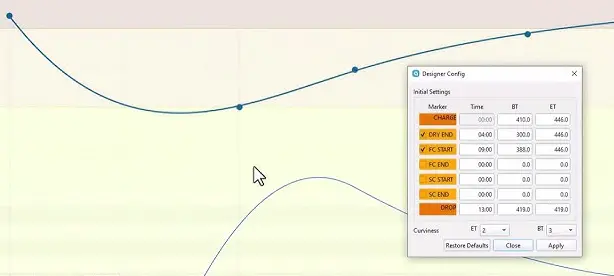

To meet this demand, roasters are turning to precision technologies that go beyond traditional color meters or manual logging of roast curves. Modern systems incorporate real-time temperature monitoring, airflow control, and automated profile replay to reduce variability. Tools like Hermetheus Co-Pilot™ analyze historical roast data, predict potential deviations, and make adjustments during the roast itself. By minimizing human error and environmental fluctuations, these technologies allow roasters to hit the same flavor targets with remarkable accuracy.

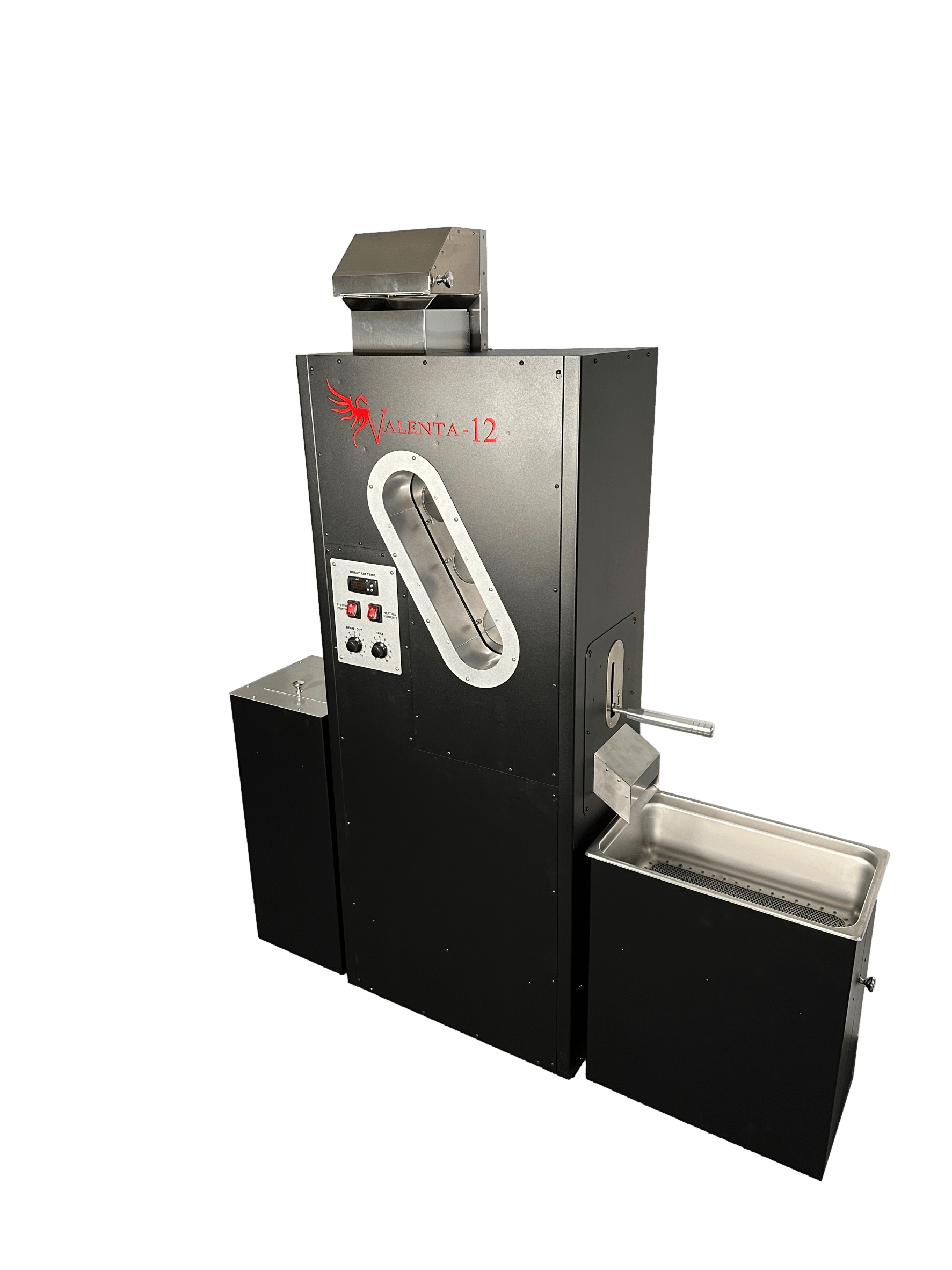

Consistency is not only about repeatable curves but also about scalability. A profile developed on a 3-kilogram machine must be reliably translated to a 12-kilogram or even a 70-kilogram roaster without losing character. This requires detailed data logging, modeling software, and often cloud-based platforms that allow operators across sites to replicate best practices. The margin for error in today’s competitive market is razor thin, and consistency is now a differentiator as much as origin or roast style.

2. Sustainability as a Differentiator

The roasting process is one of the most energy-intensive stages in coffee production, traditionally fueled by natural gas and often accompanied by high emissions. As environmental scrutiny intensifies, roasters are being asked not only to source sustainable beans but also to demonstrate that their roasting operations meet modern sustainability standards.

Forward-thinking roasters are investing in energy-efficient fluid-bed roasters, which use convective airflow rather than conductive drum heating to reduce energy consumption and shorten roast times. Others are adopting catalytic or thermal afterburners that minimize smoke and particulate emissions. These investments not only reduce carbon footprints but also help roasters comply with local environmental regulations and qualify for certifications that resonate with eco-conscious consumers.

Data-driven systems add another layer of impact. By monitoring gas consumption, exhaust temperature, and emissions in real time, roasters can identify inefficiencies and adjust processes to minimize waste. Some facilities are experimenting with renewable energy inputs—such as solar or biogas integration—to further reduce reliance on fossil fuels.

In a crowded market, sustainability is more than a compliance issue—it’s a marketing advantage. Roasters who can quantify and share their energy savings and emissions reductions strengthen their brand identity, appeal to ethically minded consumers, and secure wholesale accounts that prioritize sustainable sourcing partners.

3. Growth of Small-Batch and On-Demand Roasting

The rise of the third-wave coffee movement, direct-to-consumer subscriptions, and micro-roaster cafés has created unprecedented demand for flexible, small-batch roasting setups. Unlike large-scale commodity roasting, where uniformity and volume dominate, small-batch operations thrive on agility—roasting limited editions, experimental lots, and even single orders for online customers.

On-demand roasting systems are also emerging as a unique solution. These allow roasters to produce coffee in response to customer orders, ensuring maximum freshness and reducing inventory waste. Some café roasters market the concept of “just-roasted coffee,” where beans are roasted and packaged the same day customers purchase them, creating a premium experience tied directly to freshness.

Technological innovations are making this possible. Compact fluid-bed roasters and small drum machines now feature digital controls, profile replication, and cloud-based logging, giving micro-roasters the same precision as industrial facilities. The result is a level playing field where even start-ups can deliver consistent, high-quality coffee with distinctive roast profiles.

For consumers, this means access to unique flavor experiences, whether it’s a naturally processed Ethiopian roasted just days before delivery or a seasonal blend roasted on demand for a subscription box. For roasters, small-batch agility has become a powerful competitive advantage in a market where differentiation is critical.

4. Integration of Quality Control with Marketing

Quality control has historically been an internal process, used to validate batches, reduce defects, and meet buyer specifications. But in today’s transparency-driven marketplace, roast data itself has become a marketing asset. Roasters are increasingly sharing roast curves, consistency metrics, and flavor outcome data with customers as proof of their craftsmanship and reliability.

For example, some specialty roasters include Agtron color scores, roast dates, or even QR codes linking to roast profiles and cupping notes on packaging. Others go further, showcasing how their electrochemical or AI-powered QC systems ensure uniformity in every batch. By making the invisible data behind roasting visible to consumers, these companies turn technical precision into storytelling.

This trend aligns with the broader movement toward traceability and transparency in food and beverage industries. Just as wine lovers expect information on varietal, terroir, and vintage, coffee drinkers increasingly want to know how a roast was crafted and verified. Providing this data enhances trust, strengthens brand loyalty, and justifies premium pricing.

Internally, integrating QC with marketing has another benefit: it aligns operations and sales teams around a shared language of quality. When roasters can demonstrate consistency not only to themselves but also to wholesale buyers and end consumers, they elevate their reputation and secure long-term partnerships.

Tech Innovations in Roasting

Electrochemical Quality Control

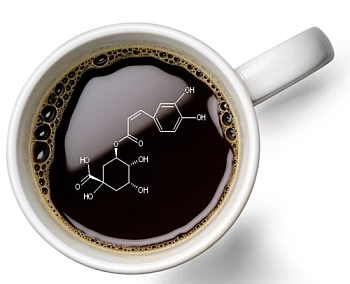

Advances in cyclic voltammetry and electrochemical sensors are providing objective markers of roast level, beverage strength, and phenolic content. These tools move beyond color measurement to capture the chemistry behind flavor, enabling a new standard of QC.

AI-Powered Roast Profiling

Machine learning platforms like Hermetheus Co-Pilot™ analyze historical roast data, predict curve drift, and suggest real-time adjustments. This shortens training times for new operators and reduces waste by keeping profiles on target.

Image Analysis and Automation

High-resolution imaging systems paired with AI can evaluate bean surface color, size distribution, and defect presence. Integrated with roast software, these systems provide immediate feedback, helping operators fine-tune batches on the fly.

Energy-Efficient Fluid-Bed Technology

Modern fluid-bed roasters are designed to reduce energy consumption while increasing roast speed and consistency. Paired with digital control systems, they offer roasters a balance of sustainability and scalability.

Cloud-Based Data Integration

Roast profiles, QC metrics, and production data are being stored and analyzed in the cloud, allowing multi-site operations to standardize output and benchmark performance across locations.

The Road Ahead

Coffee roasting is moving from intuition-driven craftsmanship toward a hybrid model where artistry is reinforced by data. The sensory expertise of the roaster—listening for first crack, watching bean color shifts, and smelling aromatic cues—will remain central, but the next generation of roasting will combine that intuition with electrochemical signatures, AI-driven roast profiling, and automated controls that make quality repeatable at scale.

We can hypothesize that in the near future, electrochemical analysis will become as commonplace in roasting labs as color meters are today. By tracking biochemical markers like chlorogenic acid degradation or melanoidin formation, roasters will be able to tie flavor outcomes directly to measurable chemical transformations rather than relying solely on color or cupping notes. This shift could give rise to a standardized “roast fingerprint,” allowing buyers across the globe to evaluate coffee quality with greater objectivity.

AI-powered control systems are likely to evolve into adaptive learning platforms. Instead of simply replaying roast curves, these systems will dynamically adjust airflow, heat application, and drum speed in response to real-time data. Over time, they will learn a roaster’s stylistic preferences—whether favoring acidity, body, or sweetness—and automatically guide profiles toward those flavor goals while minimizing energy use and waste. This predictive capacity could shorten training for new operators, reduce losses from inconsistencies, and open the door for true precision roasting.

From a sustainability perspective, the prediction is clear: energy-efficient roasters will become the new industry baseline, not a premium feature. Regulatory pressure on emissions and consumer demand for eco-conscious products will drive the adoption of catalytic afterburners, clean-burn technologies, and renewable-energy integration. The combination of reduced carbon output and transparent reporting will not only satisfy environmental standards but also enhance brand credibility in a market where consumers actively seek alignment with their values.

The implications for market differentiation are profound. In a world where many roasters source from the same farms and regions, the ability to guarantee both consistency and sustainability through technology will separate leaders from followers. Consumers may soon see packaging that includes not just roast dates and Agtron scores but also electrochemical QC metrics and carbon footprint data, turning quality control into a direct marketing tool.

Looking further ahead, we can imagine a global roasting network where profiles, data, and outcomes are shared in real time. A roaster in Portland could replicate a profile developed in Copenhagen with near-perfect fidelity, supported by cloud-based AI and standardized electrochemical markers. This level of reproducibility would enable international brands to maintain flavor identity across continents, while still allowing local roasters to infuse their personal artistry into the process.

Ultimately, these innovations won’t merely optimize efficiency—they will redefine what it means to roast coffee professionally. The future of roasting lies in the marriage of human sensory judgment with scientific precision, creating a craft that is both art and data science. Those who embrace this hybrid model will not only produce more consistent, sustainable coffee but also build reputations as pioneers in the next era of specialty coffee.

Let Coffee Crafters Help You Become A Coffee Roaster