Introduction to Coffee Degassing

What is Coffee Degassing?

Coffee degassing is the natural process by which freshly roasted coffee beans release carbon dioxide (CO₂) that has been trapped within their cellular structure during roasting. When green coffee beans are exposed to high temperatures during the roasting process, chemical reactions occur that produce significant amounts of CO₂ gas. This gas becomes embedded within the porous structure of the beans and continues to escape for days or even weeks after roasting. Understanding coffee degassing is essential for anyone serious about coffee quality, as it directly impacts the brewing process and the final flavor in your cup. Find out more about Coffee Chemistry.

The coffee degassing process begins immediately after roasting, with beans releasing CO₂ most rapidly in the first few hours and days, then gradually slowing over time. This phenomenon is why you might notice your coffee bag puffing up or why specialty coffee roasters include one-way valves on their packaging.

Importance of Degassing for Coffee Quality

The importance of coffee degassing cannot be overstated when it comes to achieving optimal flavor and brewing consistency. Excessive CO₂ in freshly roasted beans can interfere with water’s ability to extract the desirable compounds during brewing, leading to uneven extraction and potentially sour or underdeveloped flavors. When beans haven’t adequately degassed, the CO₂ creates a barrier that prevents water from fully penetrating the coffee grounds, resulting in a cup that doesn’t showcase the coffee’s true potential.

Additionally, trapped gases can cause issues with espresso brewing, creating overly aggressive channeling and excessive crema that lacks body and sweetness. Coffee freshness is a delicate balance—beans that are too fresh contain too much CO₂, while beans that have aged too long have lost their volatile aromatic compounds. Proper degassing allows the coffee to reach its flavor peak, where the CO₂ levels have stabilized enough to permit proper extraction while the beans still retain their vibrant aromatics and flavor complexity.

The Science Behind Degassing

Role of CO₂ in Coffee Beans

Carbon dioxide plays a complex and fascinating role in coffee bean chemistry and flavor development. During roasting, the intense heat triggers the Maillard reaction and caramelization, which create hundreds of flavor compounds while simultaneously producing coffee bean CO₂ as a byproduct. This CO₂ becomes trapped within the bean’s matrix, occupying the honeycomb-like cellular structure that forms during roasting as moisture evaporates and the bean expands. The gas acts as both a protective agent and a potential obstacle—on one hand, CO₂ can help preserve freshness by displacing oxygen that would otherwise cause staling through oxidation. On the other hand, excessive CO₂ interferes with the brewing process by repelling water and preventing proper extraction. The amount of CO₂ produced varies significantly based on roast level and degassing, with darker roasts generally producing and releasing more gas due to their more developed cellular structure and extended exposure to heat. The CO₂ also carries aromatic compounds with it as it escapes, which is why freshly roasted coffee smells so intoxicating but also why proper storage is crucial to prevent excessive aroma loss. Read more about Coffee Roasting.

How Coffee Beans Release CO₂

The CO₂ release coffee process occurs through multiple mechanisms and at varying rates depending on numerous factors. Immediately after roasting, beans release CO₂ rapidly through surface-level pores and microcracks that formed during the thermal expansion of roasting. This initial phase can see beans losing up to 40% of their total CO₂ content within the first 24 hours. As the surface-level gas escapes, the release rate slows considerably, with CO₂ now having to migrate from deeper within the bean’s cellular structure to the surface. Whole beans retain CO₂ much longer than ground coffee because grinding dramatically increases surface area, opening up the internal structure and allowing trapped gas to escape much more rapidly. The coffee degassing time continues at a decreasing rate over the coffee resting period, which can last anywhere from several days to several weeks depending on the bean and roast characteristics. Temperature also influences release rates, with warmer storage conditions accelerating degassing while cooler temperatures slow it down. This is why roasters and coffee professionals carefully control storage conditions to manage the degassing timeline and ensure beans reach customers at their optimal flavor window.

Factors Affecting Coffee Degassing

The Impact of Roasting on Degassing

Coffee roasting and degassing are inextricably linked, with roast development determining how much CO₂ is produced and how quickly it will be released. Light roasts, which are roasted to lower internal temperatures and shorter durations, develop less CO₂ overall and retain a denser, less porous structure that releases gas more slowly. These coffees typically require longer resting periods—sometimes 7-14 days—before they’re optimal for brewing. Medium roasts strike a balance, producing moderate amounts of CO₂ and requiring a resting period of about 4-7 days for most brewing methods. Dark roasts undergo the most dramatic transformation, with extended heat exposure creating a highly porous, brittle structure that holds more CO₂ initially but releases it much more rapidly. These beans might be ready to brew in just 2-4 days but also have a shorter overall shelf life. Roast profiles and degassing are so closely connected that experienced roasters can predict degassing behavior based on their development curves, using factors like time to first crack, total roast time, and final temperature to estimate optimal resting times for their customers.

Bean Origin and Degassing Rates

The geographic origin and processing method of coffee beans significantly influence their degassing characteristics, even when roasted to similar profiles. Beans from different regions have varying densities, moisture contents, and cellular structures that affect how they absorb heat during roasting and subsequently release CO₂. High-altitude coffees, such as those from Ethiopia or Colombia, typically grow more slowly and develop denser bean structures that may hold CO₂ longer and require extended resting periods. Lower-altitude coffees from regions like Brazil might have less dense structures that degas more quickly. Processing methods also play a role—washed coffees generally have more uniform density and predictable degassing patterns, while natural or honey-processed coffees may have less uniform structures due to fruit sugars penetrating the bean during drying, potentially affecting CO₂ retention. Even the specific variety (such as Bourbon, Typica, or Geisha) can influence coffee bean aging and degassing rates due to inherent differences in bean size, density, and chemical composition. Professional roasters often adjust their recommended resting times based on these origin characteristics to ensure optimal flavor development.

Grind Size and Its Effect on Degassing

The effect of grind size on degassing is one of the most dramatic and immediate factors coffee enthusiasts can observe. When whole beans are ground, the cellular structure is completely ruptured, increasing the surface area by hundreds or even thousands of times depending on how fine the grind is. This exponential increase in surface area causes an immediate and rapid release of trapped CO₂, which is why ground coffee smells so intensely aromatic immediately after grinding. For espresso, which uses a very fine grind, CO₂ release is so rapid that ground coffee can lose much of its gas within minutes. Coarser grinds used for methods like French press retain CO₂ slightly longer but still degas much faster than whole beans. This is precisely why coffee professionals recommend grinding immediately before brewing—not only to preserve aromatics but also to control CO₂ levels during extraction. The coffee degassing process accelerates so dramatically after grinding that pre-ground coffee, even when packaged immediately, reaches a relatively degassed state much faster than whole beans. For home brewing, this means the time between grinding and brewing becomes crucial, with most experts recommending brewing within 15-30 minutes of grinding for peak flavor, as both CO₂ and volatile aromatics dissipate rapidly once the beans are broken down.

Optimal Resting Time for Coffee

What is Resting Time?

Coffee resting time refers to the deliberate waiting period between when coffee beans are roasted and when they’re brewed, allowing the coffee degassing process to progress to an optimal level. This isn’t simply about letting the beans sit—it’s a critical window during which the coffee’s flavor potential evolves and improves. During the resting period, excessive CO₂ escapes while the beans retain their desirable aromatic compounds, creating the ideal conditions for extraction. Think of resting time as a maturation process similar to letting wine breathe or aging cheese; the coffee needs this time to reach its peak expression. The optimal coffee degassing window is when enough CO₂ has escaped to allow proper water penetration during brewing, but not so much time has passed that the coffee has begun to stale through oxidation. This sweet spot varies significantly based on the roast level, intended brewing method, and personal taste preferences. For most coffees, there’s a flavor peak that occurs somewhere between a few days and two weeks after roasting, though some exceptional coffees can maintain or even improve their characteristics for longer periods when stored properly.

Resting Time for Different Coffee Types

Different brewing methods and roast levels require tailored approaches to optimal coffee degassing, making coffee consumer education essential for getting the best results at home. For espresso, which is the most sensitive to CO₂ levels, light-to-medium roasts typically need 7-10 days of rest, while darker espresso roasts might be ready in just 3-5 days. The high pressure of espresso extraction magnifies any CO₂ issues, making proper resting critical for balanced shots without excessive sourness or channeling. Filter brewing methods like pour-over, drip, or Aeropress are more forgiving and can work well with coffee that’s been rested for 4-7 days for medium roasts, or 7-12 days for lighter roasts. French press and cold brew, which use longer contact times and don’t rely on pressure, can successfully brew coffee that’s only rested 3-5 days, though flavor will continue to improve for another several days. Darker roasts across all brewing methods generally require less resting time—sometimes as little as 2-3 days—because their more porous structure releases CO₂ more rapidly. Many coffee enthusiasts find that keeping a brewing journal helps them identify their personal preferences within these ranges, as taste is ultimately subjective and some people prefer the brighter, more aggressive character of less-rested coffee while others favor the smoother, more integrated flavors of well-rested beans.

Methods of Accelerating Degassing

Industrial Methods

Commercial roasters and specialty coffee companies employ several accelerated coffee degassing methods to manage inventory turnover and ensure consistent product quality. One common industrial approach is controlled atmospheric storage, where freshly roasted beans are held in environments with reduced oxygen levels or specific temperature and humidity controls that promote faster CO₂ release while minimizing oxidation. Some facilities use gentle agitation systems that continuously or periodically tumble beans to increase air circulation and promote gas escape from the bean surfaces.

Another technique involves the use of specialized depressurization chambers where beans are subjected to reduced atmospheric pressure, which creates a pressure differential that encourages CO₂ to migrate out of the beans more rapidly. Large-scale operations may also use nitrogen flushing systems that both displace oxygen (preventing staling) and create conditions that facilitate CO₂ release. Some premium roasters employ multi-stage cooling processes where beans are cooled slowly under controlled conditions rather than rapidly, allowing initial degassing to occur in a managed environment before packaging.

These industrial methods are designed to balance the need for faster processing times with the goal of maintaining coffee freshness and quality, ensuring that coffee reaches retail shelves at an optimal stage of degassing rather than too fresh or already staling.

At-Home Techniques

Coffee enthusiasts can employ several home coffee degassing techniques to manage freshness and optimize their brewing results without industrial equipment. The simplest method is proper storage—transferring freshly roasted beans to a container with a one-way valve allows CO₂ to escape while preventing oxygen from entering, naturally accelerating degassing while preserving freshness.

Some home roasters and enthusiasts use the “burping” technique, where they briefly open their storage container once or twice daily during the first few days after roasting to release accumulated CO₂ and allow fresh air exchange. Storing beans at slightly warmer room temperatures (rather than in the refrigerator) promotes faster degassing, though this must be balanced against the increased rate of staling at higher temperatures. Another approach is the “small batch” method, where you only grind enough coffee for immediate use, effectively controlling the degassing timeline by keeping most of your supply as whole beans.

For those who prefer working with coffee that’s past peak freshness, a technique called “bloom pre-wetting” can help—adding a small amount of water to grounds and waiting 30-45 seconds before beginning extraction, which allows residual CO₂ to escape more completely. Some enthusiasts also experiment with brief exposure to moving air from a fan, which increases convection around the beans and slightly accelerates gas release, though this method requires care to avoid excessive moisture loss or aroma dissipation.

Measuring Coffee Degassing

Tools to Measure CO₂ Release

Several tools for measuring coffee degassing have been developed for both professional and home use, ranging from simple observational methods to sophisticated analytical equipment. Professional roasting facilities often use CO₂ analyzers that measure the concentration of gas in sealed containers or headspace analyzers that quantify the CO₂ present in coffee packaging. These devices provide precise numerical data about gas release rates and remaining CO₂ levels, helping roasters fine-tune their resting recommendations. More accessible tools include simple one-way valve observation—watching how much the coffee bag inflates gives a rough indication of ongoing CO₂ release, with rapid inflation indicating high gas production.

Some specialty coffee companies have developed simple pressure-measuring devices that attach to storage containers, providing a relative indication of internal pressure changes over time as CO₂ escapes. For home users, there are now affordable handheld CO₂ meters designed for coffee applications, though these vary in accuracy and ease of use. Another creative measurement approach involves the water displacement method, where beans are submerged in water and the volume of CO₂ bubbles released over a set time period provides a relative measure of degassing activity. Digital scales with high precision can also track very slight weight changes as CO₂ escapes, though this requires extremely sensitive equipment and controlled conditions to be meaningful.

Signs of Adequate Degassing

Recognizing the signs of coffee degassing doesn’t always require specialized equipment—experienced coffee professionals and enthusiasts can assess degassing status through careful observation and brewing tests. The most obvious visual indicator is the behavior of coffee packaging; a severely inflated bag indicates active degassing, while a relatively flat bag suggests the process has largely completed. When brewing, the “bloom” phase of pour-over coffee provides excellent feedback—overly fresh coffee will produce an aggressive, volcano-like bloom with large bubbles and dramatic expansion, sometimes even overflowing the brewing cone.

Properly degassed coffee blooms more gently, with smaller, more uniform bubbles and controlled expansion that settles into an even bed. During espresso extraction, over-gassed beans produce shots that channel easily, spray excessively during the first few seconds, and develop unusually thick, bubbly crema that dissipates quickly and tastes harsh. Adequately rested espresso flows more evenly, produces creamy, stable crema with a pleasant texture, and exhibits balanced extraction. The aroma profile also provides clues—extremely fresh coffee often smells sharply acidic or grassy, while properly rested coffee presents more integrated, complex aromatics.

In the cup, coffee that hasn’t rested enough often tastes sour, astringent, or “green,” with flavors that seem disconnected rather than harmonious. Assessing coffee freshness through these signs becomes intuitive with practice, allowing coffee lovers to dial in their preferences without needing expensive measurement equipment.

Let Coffee Crafters Help You Become A Coffee Roaster

The Brew Impact

How Degassing Influences Brewing

The relationship between coffee degassing and the brewing process is fundamental to achieving consistent, high-quality results across all preparation methods. When CO₂ release during brewing is excessive, the gas creates physical barriers that prevent water from evenly saturating the coffee grounds. In pour-over brewing, this manifests as uneven wetting, with water flowing around rather than through certain areas of the coffee bed, leading to under-extraction in some areas and over-extraction in others. For espresso, the high-pressure environment amplifies these issues—trapped CO₂ seeks escape routes through the puck, creating channels where water flows preferentially, resulting in gushing, uneven shots with sour and bitter notes combined unpleasantly. In immersion methods like French press, excessive CO₂ causes grounds to float rather than settle, making it difficult to achieve even extraction and clean separation during plunging. The coffee brewing flavors are profoundly affected by degassing status; under-rested coffee typically produces bright, acidic, sometimes harsh flavors with limited body and sweetness, as the CO₂ prevents adequate extraction of the pleasant, soluble compounds that provide balance and complexity. As beans properly degas, extraction becomes more even and complete, allowing sugars, oils, and nuanced flavor compounds to fully dissolve, resulting in cups with better body, sweetness, and integration of flavors.

Flavor Profile and Resting Time

The evolution of flavor profiles during the coffee resting period is a dynamic journey that reveals different characteristics of the coffee at various stages. In the first 24-48 hours after roasting, coffees often present sharp, one-dimensional flavors dominated by acidity and sometimes displaying grassy or vegetal notes that haven’t fully mellowed. These early-stage flavor preservation characteristics lack the complexity that develops with proper rest. As degassing coffee beans progress through days 3-5, flavors begin to integrate and mellow, with sweetness becoming more apparent and acidic notes taking on more pleasant, fruit-like qualities rather than sharp tartness.

The coffee’s body typically increases during this period as CO₂ levels decrease and allow more complete extraction. During the optimal window—usually days 5-14 depending on roast level—the coffee reaches its peak expression, with all flavor components harmoniously balanced, aromatic complexity at its height, and texture at its fullest. Bright acidity is present but supported by sweetness and body rather than dominating the profile. After this peak period, coffee bean aging continues but shifts from improvement to gradual decline; beyond 2-3 weeks for most coffees, aromatic compounds begin to fade through oxidation, flavors become flat or cardboard-like, and the vibrant character that defined the coffee’s peak begins to disappear.

Understanding this flavor timeline helps coffee lovers plan their purchases and consumption to experience coffee at its best, whether that means buying smaller quantities more frequently or learning to appreciate different characteristics at various stages of the resting period.

The Role of Coffee Bags in Degassing

Types of Coffee Bags

Modern coffee packaging has evolved significantly to address the challenges of coffee bag venting while maintaining freshness and quality. The most common and effective design is the one-way valve bag, which features a small plastic or metal valve that allows CO₂ to escape from the sealed bag while preventing oxygen and moisture from entering. These valves are essential for packaging freshly roasted coffee, as they prevent bag rupture from CO₂ buildup while maintaining an oxygen-free environment that slows staling. High-end one-way valves can release gas efficiently while maintaining seal integrity for months.

Another option is the tin-tie bag with micro-perforations, commonly seen in craft coffee roasteries; while these allow degassing, they’re less protective against oxygen infiltration and are typically used for coffee intended for quick consumption. Some roasters use nitrogen-flushed bags without valves, where oxygen is displaced with inert nitrogen gas before sealing, though these require that coffee be pre-rested before packaging to avoid dangerous pressure buildup. Premium types of coffee packaging include multi-layer foil bags with excellent barrier properties against light, oxygen, and moisture, combined with high-quality one-way valves. Newer innovations include biodegradable materials with integrated valve systems that maintain performance while addressing environmental concerns, and some specialty roasters are experimenting with glass jars with pressure-release valves for a more sustainable, reusable option.

How Bags Affect Degassing and Flavor Preservation

The types of coffee packaging directly influence both the degassing timeline and long-term flavor preservation in coffee, making packaging selection a critical consideration for roasters. Bags with efficient one-way valves promote optimal degassing by allowing CO₂ to escape freely while maintaining an oxygen-free internal environment. This creates ideal conditions where coffee can degas naturally without the negative effects of oxidation that would occur in permeable or frequently opened containers.

The material composition matters significantly—multi-layer bags with aluminum or metalized films provide superior oxygen barriers compared to single-layer plastics, dramatically extending the period during which coffee maintains its peak flavor characteristics. Transparent bags, while visually appealing for retail display, expose coffee to light that degrades flavor compounds and accelerates staling, making opaque packaging preferable for quality retention. Bag size also influences outcomes; coffee packaged in quantities that match typical consumption patterns (8-12 oz bags for home use) experiences less oxygen exposure than large format bags that remain open for extended periods.

The timing of packaging relative to roasting affects flavor preservation—coffee packaged immediately after roasting in proper valve bags can maintain quality longer than coffee that degasses in open containers before packaging, as the latter experiences oxidation during the initial high-activity degassing phase. Some specialty roasters are now providing specific guidance on their packaging, indicating optimal opening dates or recommending storage techniques, helping consumers maximize the importance of coffee degassing and freshness throughout the coffee’s life.

Professional Insights

Barista Perspective

Experienced baristas develop an intimate understanding of barista tips on coffee degassing through daily interaction with coffee at various stages of rest. Professional baristas working with espresso are particularly attuned to degassing status because espresso preparation is so sensitive to CO₂ levels; they often receive deliveries of freshly roasted coffee and must adjust their approach as the coffee evolves throughout the week. Many report that espresso requires the most patience, with light roasts sometimes not reaching their potential until 10-12 days post-roast, while darker blends might be serviceable at 3-4 days but continue improving through day 7. Skilled baristas adjust their grinding and brewing parameters to compensate for degassing status—using slightly coarser grinds and higher doses for under-rested coffee, or tightening up the grind as coffee reaches its peak. They also recognize that “bloom pre-infusion” techniques, where a small amount of low-pressure water is applied before full extraction begins, can help manage excessive CO₂ in fresher beans.

Many baristas advocate for coffee rotation systems where multiple roast dates are available simultaneously, allowing them to serve coffee at its peak while newer batches rest. They emphasize to customers that the “roasted on” date is more meaningful than a generic “best by” date, and that coffee consumed between 5-14 days after roasting typically represents the sweet spot for most brewing methods. Their practical experience reinforces that while coffee science provides guidelines, personal preference plays a significant role—some customers genuinely prefer the bright, vibrant character of 3-day-old coffee, while others favor the more integrated, smooth profile of 10-day-old beans.

Roaster Insights

Coffee roasters provide invaluable perspectives on roast profiles and degassing, as they witness the entire transformation from green bean to packaged product and receive direct feedback from customers about optimal timing. Experienced roasters explain that degassing behavior is partly predictable based on roast development—they can estimate degassing curves based on factors like bean density, roast degree, and cooling method.

Many roasters intentionally adjust their roast profiles to influence degassing characteristics; for instance, a slower, more developed roast may produce coffee that reaches optimal flavor slightly sooner than a very light, fast roast of the same origin. Roasters emphasize that coffee roasting and degassing aren’t separate considerations but interconnected aspects of the same process. They note that ambient conditions in the roastery affect outcomes—humidity, temperature, and even barometric pressure can influence how quickly beans cool and begin releasing CO₂.

Professional roasters often maintain detailed records correlating roast profiles with customer feedback about peak flavor timing, refining their recommendations over years of accumulated data. Many are moving toward more sophisticated packaging strategies, such as resting coffee for 3-5 days before packaging to allow the most aggressive degassing to occur, then sealing with one-way valves for optimal freshness during shipment and storage.

Roasters also acknowledge the challenge of balancing business realities with quality—while coffee might be optimal at 7-10 days post-roast, market demands and shipping times mean that customers often receive coffee at various stages of rest, making education about proper storage and the coffee resting period essential for customer satisfaction.

Consumer Awareness

Importance of Resting Time

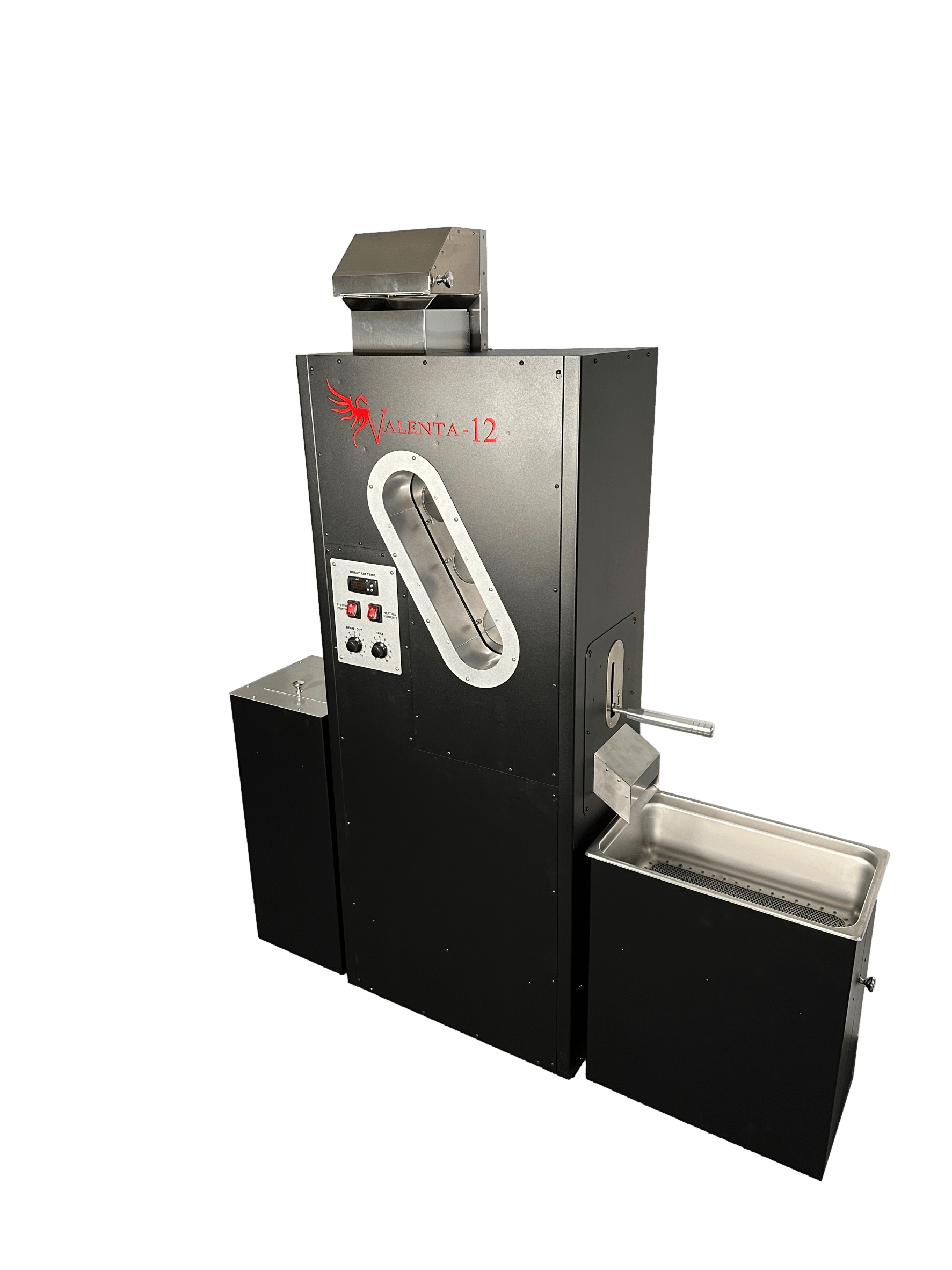

Educating consumers about the importance of resting time represents one of the most significant gaps in coffee consumer education today. Many coffee drinkers purchase freshly roasted beans with excitement, only to brew them immediately and wonder why their expensive specialty coffee tastes sharp, sour, or unbalanced. What’s interesting is that even images—such as the one above mistakenly showing green coffee beans being dropped into a cooling tray of fully roasted beans—can unintentionally reinforce misunderstanding about the roasting and degassing process.

In reality, degassing begins only after roasting is complete, and the amount of CO₂ escaping during those early hours directly shapes the eventual flavor profile, body, and sweetness of the cup. Understanding that coffee needs time to reach its potential transforms the purchasing and consumption experience. Consumers who grasp this concept begin to plan their coffee buying more strategically, perhaps ordering beans timed to arrive when their current supply is running low, ensuring continuous access to properly rested coffee.

The importance of coffee degassing extends beyond just flavor—it affects brewing consistency, equipment performance (particularly for espresso machines where excessive CO₂ can cause pressure irregularities), and even the educational experience of learning to brew better coffee. When variables like degassing status aren’t controlled, it becomes nearly impossible to troubleshoot other brewing variables, leading to frustration and inconsistent results. Forward-thinking roasters address this through clear roast-date labeling, educational materials included with shipments, and even “drink after” recommendations on packaging. Some direct-to-consumer coffee subscriptions have begun building rest time into their shipping schedules, intentionally delaying shipment for several days after roasting so coffee arrives closer to its peak window.

Consumer awareness also extends to understanding that “freshness” doesn’t simply mean “as close to roasting as possible” but rather finding the optimal window where coffee has rested enough but hasn’t aged too much—typically a sweet spot that runs from about 5 days to 3 weeks post-roast for most coffees when properly stored.

How to Assess Freshness at Home

Developing skills for assessing coffee freshness at home empowers consumers to make informed decisions about their coffee purchases and brewing practices. The most fundamental step is always checking the roast date on packaging—reputable specialty roasters prominently display this information, and its absence is often a red flag suggesting pre-roasted coffee of indeterminate age. Once you have dated coffee, calculating where it falls in the degassing timeline helps set expectations; coffee delivered 3 days post-roast needs patience, while beans arriving 10 days out should be ready to brew immediately.

Visual assessment of the beans themselves provides clues—freshly roasted beans often have a shinier, oilier appearance (especially for darker roasts) that gradually becomes duller as oils are absorbed or oxidized; however, extremely oily beans on light roasts might indicate age rather than freshness. The smell test is remarkably informative; opening a bag of properly fresh, well-rested coffee releases a powerful, complex aroma, while stale coffee smells flat, cardboard-like, or musty. During brewing, observing the bloom behavior helps assess freshness—a vigorous bloom indicates active degassing (possibly too fresh), a gentle bloom suggests optimal rest, and no bloom at all signals stale coffee.

Home assessment also includes taste evaluation; taking notes on how the same coffee tastes at different stages of rest helps you identify your personal preference within the optimal window. Storage practices matter enormously—transferring beans to an airtight container with a one-way valve, keeping them in a cool, dark place, and minimizing oxygen exposure extends the period during which coffee remains fresh. Finally, purchasing patterns can be optimized; buying smaller quantities more frequently, perhaps 250g or 12oz bags that you’ll consume within 1-2 weeks of opening, ensures you’re always drinking coffee near its peak rather than watching a large bag gradually decline in quality over a month or more.

Let Coffee Crafters Help You Become A Coffee Roaster

FAQ Section

Top Questions

How long should I wait before brewing freshly roasted coffee? The coffee degassing FAQ most frequently addresses this fundamental question, and the answer depends on your brewing method and roast level. For espresso with light-to-medium roasts, wait 7-10 days; for espresso with darker roasts, 3-5 days is usually sufficient. Filter brewing methods like pour-over work well with coffee rested 5-7 days for medium roasts or 7-12 days for light roasts. French press and other immersion methods are more forgiving and can successfully brew coffee at 3-7 days post-roast.

Can I speed up the degassing process? While accelerated coffee degassing methods exist for commercial operations, home users should generally allow natural degassing to occur. However, storing beans in a container with a one-way valve at room temperature (not refrigerated) promotes optimal gas release, and briefly opening the container daily during the first few days can help. Grinding coffee immediately accelerates degassing but should only be done just before brewing for freshness.

How do I know if my coffee has degassed enough? Signs of adequate degassing include moderate bloom during brewing (not excessive or absent), balanced flavor without sharp sourness, and stable espresso extraction without extreme channeling or gushing. If coffee tastes overly acidic, astringent, or “green,” it likely needs more rest time.

Does ground coffee degas faster than whole beans? Yes, dramatically so. The effect of grind size on degassing is exponential—ground coffee loses most of its CO₂ within minutes to hours, while whole beans degas over days to weeks. This is why grinding just before brewing is essential for optimal flavor.

How long does fresh coffee stay fresh? When properly stored in a one-way valve bag or airtight container, coffee typically remains at peak quality for 2-3 weeks after roasting, though it remains acceptable for 4-6 weeks. After this, staling from oxidation increasingly dominates, and flavors become flat regardless of degassing status.

Can I freeze coffee to preserve freshness? Freezing can extend coffee freshness if done properly—use airtight, moisture-proof packaging, freeze immediately after the initial degassing period (around 5-7 days post-roast), and allow coffee to return to room temperature before opening the container to prevent condensation. However, flavor preservation in coffee is best achieved through timely consumption rather than long-term storage.

Conclusion

Summary

Understanding coffee degassing and resting time transforms coffee from a simple commodity into a dynamic product that requires knowledge and timing to appreciate fully. The coffee degassing process—the natural release of CO₂ from freshly roasted beans—profoundly impacts brewing success and flavor development, making it one of the most critical yet often overlooked aspects of coffee preparation. We’ve explored how CO₂ release coffee begins during roasting and continues for weeks afterward, influenced by factors including roast level and degassing relationships, bean origin and density, and grind size.

The science behind degassing reveals that while CO₂ initially protects coffee from oxidation, excessive gas interferes with brewing by preventing proper water contact and extraction. Optimal coffee degassing occurs when beans have released enough CO₂ to brew properly but retain their volatile aromatics and haven’t yet begun to stale—typically a window between 5-14 days post-roast for most coffees and brewing methods. Different approaches exist for both commercial and home coffee degassing, from sophisticated industrial systems to simple at-home storage practices.

The importance of coffee degassing extends to professionals and consumers alike; baristas and roasters have developed deep expertise in managing degassing for optimal results, while informed consumers can dramatically improve their coffee experience by understanding resting periods, proper storage, and freshness assessment techniques. The future of coffee degassing will likely bring increased transparency, better packaging technologies, and continued consumer education, helping more people access the exceptional flavors that properly rested coffee delivers.

Future Trends

The future of coffee degassing promises exciting developments in technology, packaging, and consumer engagement as the specialty coffee industry continues to mature. Emerging technologies sparked by topics like Electrochemical Profiling of Coffee Quality, are making tools for measuring coffee degassing more accessible and affordable, with smartphone-connected devices and simple chemical indicators that could eventually allow consumers to objectively assess degassing status rather than relying on estimation and experience.

Packaging innovation continues evolving, with biodegradable materials that maintain the protective properties of current multi-layer bags, smart packaging with integrated freshness indicators that change color based on degassing status, and even time-release valve systems that adjust their permeability as coffee ages. Roasters are increasingly adopting precision approaches, using data analytics and customer feedback to provide specific “brew after” dates tailored to different origins and roast profiles rather than generic waiting periods.

The trend toward transparency in specialty coffee extends to degassing education, with more producers offering detailed information about their specific coffees’ degassing characteristics and optimal brewing windows. Subscription services are incorporating degassing considerations into their logistics, coordinating roasting and shipping schedules to ensure coffee arrives at subscribers’ homes closer to peak freshness.

Some forward-thinking companies are exploring pre-degassing services where coffee is intentionally held for several days in controlled conditions before shipment, essentially starting customers’ coffee at the optimal stage. Technology may even enable real-time monitoring, with some experimental systems using IoT devices to track CO₂ levels in coffee storage containers and alert users when their coffee reaches optimal brewing condition. As coffee consumer education continues expanding through social media, educational content, and community engagement, we can expect future generations of coffee enthusiasts to view degassing awareness as fundamental rather than specialized knowledge.

Further Reading

For those interested in deepening their understanding of coffee degassing and the broader science of coffee preparation, numerous resources provide detailed exploration of these topics. The Specialty Coffee Association (SCA) offers extensive technical documentation on coffee roasting and degassing through their online resources and professional certifications (https://sca.coffee/), including detailed papers on CO₂ production during roasting and its effects on extraction.

Books such as The Coffee Roaster’s Companion by Scott Rao (https://www.scottrao.com/products/the-coffee-roasters-companion) and The World Atlas of Coffee by James Hoffmann (https://www.amazon.com/World-Atlas-Coffee-James-Hoffmann/dp/1784724639) provide accessible yet thorough discussions of degassing within broader coffee contexts, while Espresso Coffee: The Science of Quality by Andrea Illy and Rinantonio Viani (https://www.elsevier.com/books/espresso-coffee/illy/978-0-12-370371-2) delivers deep scientific analysis of CO₂’s role in coffee quality.

Online communities like Home-Barista (https://www.home-barista.com/) and r/Coffee on Reddit(https://www.reddit.com/r/Coffee/) feature extensive discussions from experienced enthusiasts sharing practical experiences with coffee resting time and brewing optimization.

Barista Hustle’s educational platform (https://www.baristahustle.com/) offers detailed courses and articles specifically addressing degassing science and practical applications for both professional and home brewers.

Coffee roasting forums such as CoffeeGeek (https://www.coffeegeek.com/) and Roast Magazine(https://www.roastmagazine.com/) provide professional insights from industry insiders about roast profiles and degassing management.

Research papers published in the Journal of Agricultural and Food Chemistry (https://pubs.acs.org/journal/jafcau) and Food Chemistry (https://www.sciencedirect.com/journal/food-chemistry) offer rigorous scientific studies on CO₂ release dynamics, volatile compound preservation, and the chemistry of coffee aging.

Many specialty coffee roasters maintain educational blogs discussing their specific approaches to degassing recommendations and coffee freshness, providing real-world perspectives from professionals managing these variables daily.

YouTube channels by coffee experts like James Hoffmann (https://www.youtube.com/user/jimseven), Chris Baca(https://www.youtube.com/c/RealChrisBaca), and Morgan Drinks Coffee(https://www.youtube.com/c/morgandrinkscoffee) offer video demonstrations of degassing effects on brewing and practical guidance for home coffee enthusiasts.

For those interested in coffee brewing flavors and how degassing influences taste, resources from the SCA Coffee Taster’s Flavor Wheel (https://sca.coffee/research/coffee-tasters-flavor-wheel) and accompanying sensory guides help develop the skills needed to identify how degassing status affects the cup, ultimately empowering coffee lovers to explore and optimize their own perfect timing for coffee enjoyment.

Further on-site reading: The Perfect Roast.