Table Of Contents:

- What Is Roast Process Automation and How Does Hermetheus Co-Pilot™ Enhance It?

- How Does Hermetheus Co-Pilot™ Ensure Roast Consistency?

- Main Features and Benefits of Hermetheus Co-Pilot™ for Roasters

- How AI-Powered Roast Management Improves Efficiency

- Solutions for Different Roasting Business Models

- Measurable Benefits of Hermetheus Co-Pilot™

- Getting Started with Hermetheus Co-Pilot™

- Frequently Asked Questions

- Final Thoughts

What Is Roast Process Automation and How Does Hermetheus Co-Pilot™ Enhance It?

Roast process automation uses software control to manage the full cycle—from charge to drop—against a target profile. Hermetheus Co-Pilot™ connects to Valenta roasters to read bean temp, exhaust temp, and rate-of-rise, then applies micro-adjustments to heat and airflow in real time. The result is a tighter curve, less operator fatigue, and fewer missed targets.

Core Advantages:

- Standardized roast profiles for each origin and blend

- Automatic data logging for QC and training

- Operator prompts for charge, first crack, and drop timing

How Does Hermetheus Co-Pilot™ Ensure Roast Consistency?

Consistency comes from repeatable control. Co-Pilot™ stores your proven profiles and follows them batch after batch. Adaptive logic accounts for ambient temperature, green coffee moisture, and density shifts, keeping your rate-of-rise on track and your flavor outcomes uniform across production days.

What You’ll Notice in the Cup:

- Stable development time and even color

- Reduced under- or over-development

- Fewer throwaway batches and tighter inventory planning

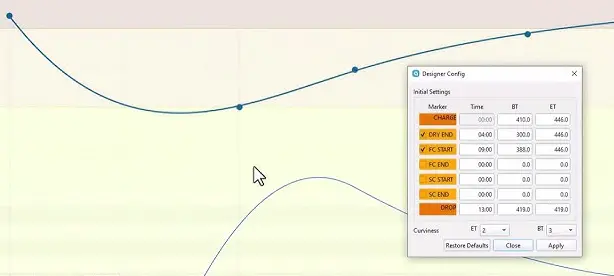

Main Features and Benefits of Hermetheus Co-Pilot™ for Roasters

- Profile Replication: Follow target curves automatically with manual override available at any time

- Live Dashboards: Bean temp, exhaust temp, ROR, energy application, and event markers in one view

- Recipe Library: Save, version, and recall profiles per origin, process, and batch size

- Auto Logging: Every roast captured for QC, cupping notes, and client reporting

- Valenta Integration: Tuned for Coffee Crafters’ efficient fluid-bed heat dynamics

How AI-Powered Roast Management Improves Efficiency

Co-Pilot™ analyzes your historical roasts to predict curve drift and adjusts earlier in the cycle, reducing corrections later. Training time drops because operators follow clear prompts, while production increases thanks to fewer outliers and smoother back-to-back batches.

| Scenario | Co-Pilot™ Action | Resulting Benefit |

|---|---|---|

| Ambient temperature rises mid-roast | Automatically reduces heat earlier to maintain target rate-of-rise | Prevents overdevelopment and maintains flavor consistency |

| Green coffee with higher moisture content | Increases airflow and adjusts heat curve during early drying stage | Ensures even moisture release and prevents baked flavors |

| Operator starts roast slightly late | Dynamically shifts profile timing to realign with target curve | Saves the batch without sacrificing quality |

| Successive back-to-back batches | Learns from previous batch exhaust temps and pre-heats optimally | Shorter turnaround between roasts, higher throughput |

| New trainee operating roaster | Provides real-time prompts for charge, first crack, and drop | Reduces training time and minimizes costly mistakes |

Solutions for Different Roasting Business Models

- Small-Batch Specialty: Dial in single origins and replicate for wholesale without flavor drift

- Wholesale Production: Lock profiles to fulfill larger POs with uniformity and predictable yield

- Private Label: Store client-specific recipes and switch fast between SKUs without recalibration stress

Measurable Benefits of Hermetheus Co-Pilot™

- Lower roast variability and tighter COGS per pound

- Faster operator onboarding and fewer manual errors

- Higher repeat sales through consistent flavor delivery

- Actionable production data for planning and QA

Hermethus Co-Pilot™ delivers tangible, data-backed improvements to coffee roasting operations by enhancing consistency, efficiency, and overall product quality. By automating key roast controls and integrating intelligent adjustments in real time, it reduces batch-to-batch variability, leading to more uniform flavor profiles and fewer defects. This consistency not only strengthens customer satisfaction but also drives repeat sales and brand loyalty.

Operationally, Co-Pilot™ shortens training time for new operators by as much as 50%, since the software handles precise heat and airflow management while providing clear prompts for key roast events. For established teams, this translates into more roasts per day with fewer errors, reducing waste and cutting production costs. By capturing and storing complete roast data for every batch, Co-Pilot™ also gives roasters valuable insights into performance trends, helping to optimize scheduling, manage green coffee inventory more effectively, and plan for growth.

The combined effect is a roasting system that produces higher-quality coffee, more efficiently, with predictable results—allowing both small-batch and high-volume roasteries to scale with confidence and profitability.

Getting Started with Hermetheus Co-Pilot™

- Buy A Valenta 18: See live control, dashboards, and profile management stock on this Valenta 18 roaster

- Install & Calibrate: Connect to your roaster, set sensors, and load starter profiles

- Train & Launch: Build recipes for key SKUs and start logging production-ready batches

Frequently Asked Questions

Does Hermetheus Co-Pilot™ work with all Coffee Crafters models?

It’s built for the Valenta series to match the roaster’s fluid-bed characteristics and deliver the best control response.

Can I roast manually?

Yes. You can switch between manual control and Co-Pilot™ at any point in the roast.

Will it improve my roast quality?

Consistency drives quality. By controlling ROR and key events, Co-Pilot™ helps you hit your target profile more reliably.

What about data ownership?

Your roast data and profiles remain yours for QC, training, and reporting.

How does Hermetheus Co-Pilot™ store and manage roast profiles?

Hermetheus Co-Pilot™ saves each profile with full temperature curves, event markers, and roast notes, allowing you to recall and replicate them at any time for consistent results.

Is Hermetheus Co-Pilot™ difficult to install on my Valenta roaster?

No. It’s designed for straightforward integration with the Valenta series, with guided setup and calibration support provided by Coffee Crafters’ technical team.

Can Hermetheus Co-Pilot™ handle multiple coffee origins in one production day?

Yes. You can store unique profiles for each origin or blend and switch between them instantly, minimizing downtime and ensuring every batch meets its intended flavor target.

Does Hermetheus Co-Pilot™ require an internet connection to operate?

No. All core roasting functions operate locally, ensuring reliability even without an internet connection. An internet connection is only needed for updates, remote support, and optional cloud data storage.

Will Hermetheus Co-Pilot™ reduce waste and save on production costs?

Yes. By maintaining precise control over roast curves, Hermetheus Co-Pilot™ reduces underdeveloped or over-roasted batches, cutting waste and maximizing your yield from every pound of green coffee.

Is there ongoing support after purchase?

Absolutely. Coffee Crafters provides technical assistance, training resources, and software updates to ensure your Hermetheus Co-Pilot™ system continues to perform at its best over the long term.

Final Thoughts

Hermethus Co-Pilot™ transforms the Coffee Crafters Valenta roaster from an already powerful fluid-bed machine into a fully optimized, precision-driven production system built around data, repeatability, and ease of use. By integrating intelligent roast management software directly with your roaster’s controls and sensors, Co-Pilot™ monitors every key variable—bean temperature, exhaust temperature, rate-of-rise, and airflow—while making automated adjustments in real time to ensure the roast curve stays exactly on target.

For new operators, this means the steep learning curve often associated with mastering roast control is dramatically shortened. Instead of months of trial and error to achieve consistent results, Co-Pilot™ guides them through each stage of the roast, automating critical transitions like first crack and development time so they can focus on understanding flavor development without worrying about missing key events.For experienced roasters, Hermethus Co-Pilot™ becomes a tool for scaling operations with confidence. It locks in your best profiles and replicates them batch after batch, regardless of environmental changes or production volume, ensuring that customers receive the same great coffee every time.

By removing the variability that can creep into manual roasting, it not only safeguards quality but also reduces waste, improves production efficiency, and frees up skilled operators to focus on sourcing, blending, and growing the business. The result is a system that delivers the holy grail of roasting—consistent, repeatable quality at scale—alongside actionable production insights that help you plan more effectively, meet demand reliably, and maximize profitability. With Hermetheus Co-Pilot™, your Valenta roaster becomes more than a machine—it becomes the foundation of a streamlined, data-backed roasting operation designed for long-term success.